Reading Time: 4 minutes

Key Points:

- Regular maintenance is key to prolonging the life of pipe relining equipment.

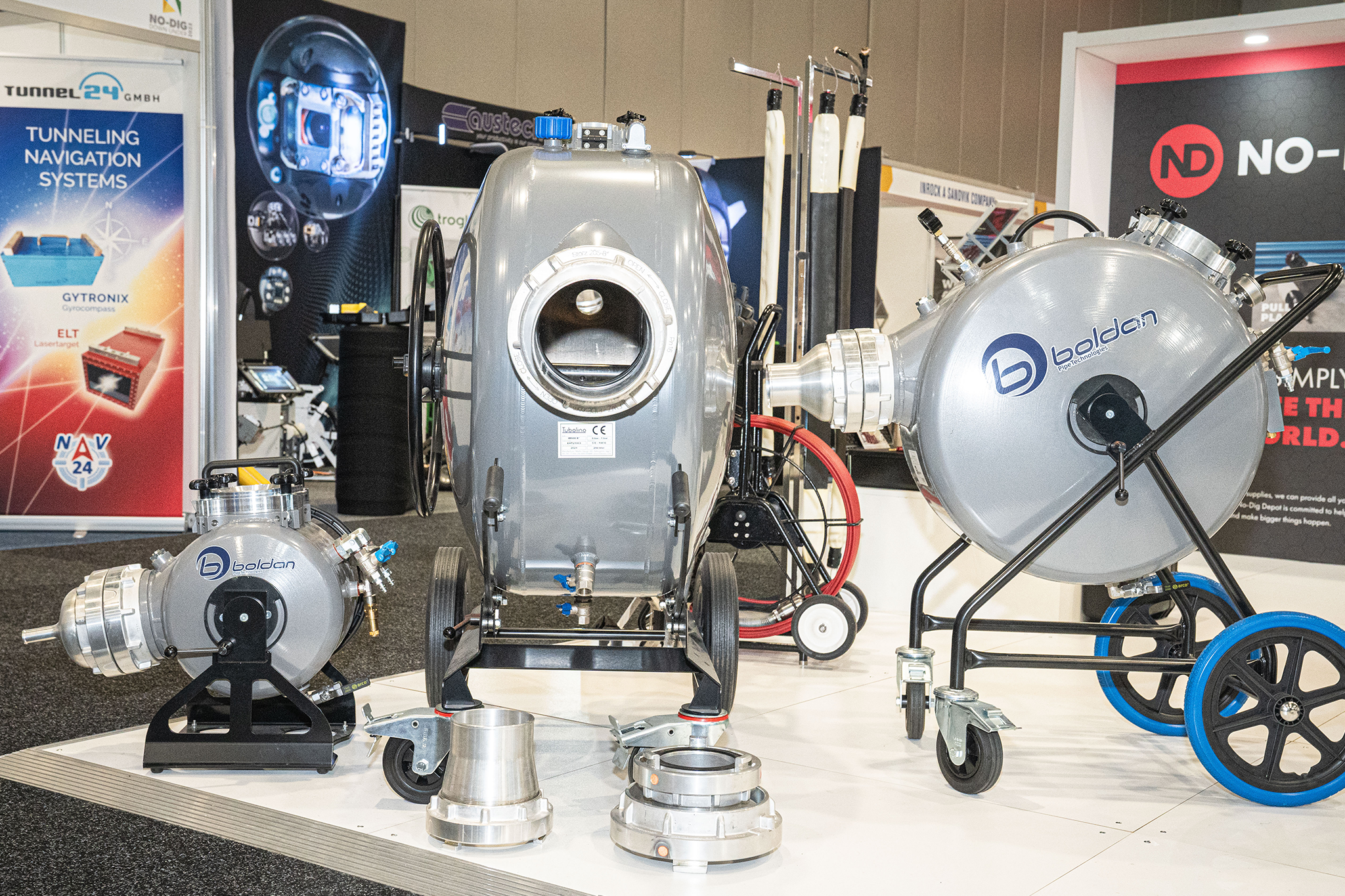

- Proper care of tools like inversion drums, PIP systems, and Boldan rollers can prevent costly repairs.

- No-Dig Depot offers durable, high-quality relining equipment and expert advice on how to maintain it.

- Preventive maintenance ensures equipment reliability and optimal performance for every project.

Your pipe relining equipment is the backbone of your business. From inversion drums to resin applicators, keeping these tools in top condition can save you time, money, and frustration on the job. Regular maintenance is crucial for preventing wear and tear, ensuring equipment longevity, and optimising performance. In this blog, we’ll share practical tips on maintaining your pipe relining tools to help you get the most out of your investment.

Clean Equipment After Every Job

A simple but essential step in equipment maintenance is cleaning after each job. Residual resin, debris, and dirt can build up on inversion drums, rollers, and hoses, leading to clogging or damage over time. Use appropriate cleaning solutions designed for relining tools to ensure you don’t accidentally degrade equipment parts.

- Clean inversion drums and hoses thoroughly after every job.

- Remove any resin build-up from rollers to maintain smooth operation.

- Wipe down handles, controls, and other external parts to prevent dirt from causing wear.

Inspect and Replace Worn Parts

One of the easiest ways to extend the life of your pipe relining tools is by regularly inspecting them for signs of wear. Over time, parts like hoses, seals, bearings, connections, and rollers can degrade, especially with frequent use. Regular checks allow you to catch these issues early, avoiding costly breakdowns during critical projects.

At No-Dig Depot, we supply high-quality parts and consumables for a wide range of relining tools. If you notice any signs of wear, like leaks or decreased pressure, it may be time to replace specific components.

- Check hoses for leaks or cracks before and after each job.

- Inspect seals and connections on PIP PACKER (Pull-In-Place) systems to ensure they’re functioning correctly.

- Replace worn rollers on inversion equipment to maintain operational efficiency.

Lubricate Moving Parts

Keeping the moving parts of your pipe relining equipment well-lubricated is critical for smooth operation. Whether it’s the drum of your inversion system or rollers on your curing machines, proper lubrication helps to prevent friction, which can cause damage over time. Use high-quality lubricants designed for industrial use to ensure long-lasting protection.

- Lubricate drum rollers and bearings on inversion systems regularly.

- Apply a small amount of lubricant to moving joints and handles for easy operation.

Store Equipment Properly

Storing your equipment properly between jobs is just as important as cleaning and maintaining it. Exposure to extreme temperatures, moisture, or direct sunlight can shorten the lifespan of your relining tools. Ensure that your equipment is stored in a dry, secure location to protect it from these elements.

At No-Dig Depot, we offer durable Boldan equipment that is built to last, but even the best tools need the right care and storage conditions.

- Store your inversion drums in a cool, dry place away from direct sunlight.

- Keep hoses coiled neatly to avoid kinks or damage when not in use.

- Use protective covers on larger equipment to prevent dust build-up.

Schedule Regular Professional Servicing

Even with regular cleaning and inspections, scheduling periodic professional servicing is a smart investment in your equipment’s longevity. Certified technicians can identify issues you might overlook, perform deep cleaning, and replace critical components when needed.

At No-Dig Depot, we provide expert advice and can connect you with trusted service providers to ensure your equipment continues to perform at its best.

Final Thoughts

Maintaining your pipe relining equipment doesn’t have to be complicated, but it does require consistency. By cleaning your tools, inspecting for wear, lubricating moving parts, and storing everything properly, you’ll ensure your equipment lasts for years to come. Partner with No-Dig Depot to access top-tier relining tools and consumables, along with the expert guidance you need to keep your equipment in prime condition. Contact us today for more information on our products and services.